Applied Engineering & Functional Prototyping

Creating replacement parts and solving real-world problems through engineering design and 3D printing.

Duration

Ongoing

Team

Solo Projects

Status

Active

Overview

Drawing on my knowledge of material properties and solid mechanics, I've learned how to identify weak points in designs and select appropriate materials for repairs or replacements.

Objectives

Identify mechanical failure points in existing designs

Create improved replacement parts using 3D printing

Apply engineering principles to solve real-world problems

Optimize designs for strength, durability, and functionality

Process & Methodology

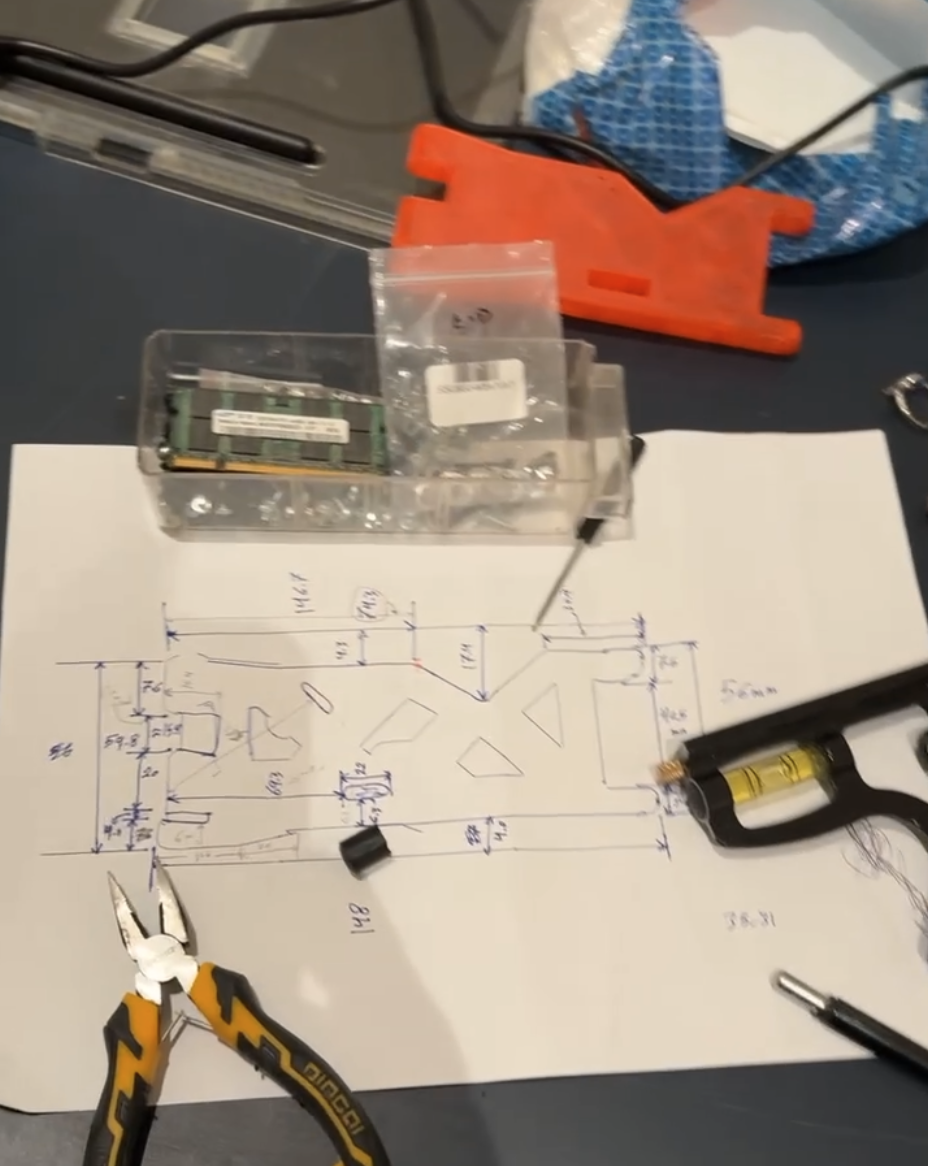

Identify weak points in existing designs and analyze the root causes of mechanical failures.

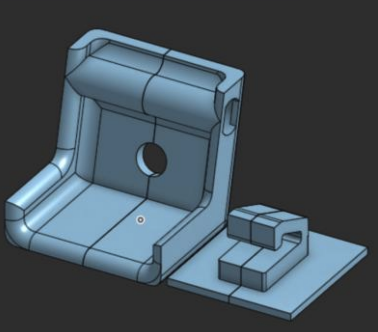

Create improved designs using OnShape, incorporating engineering principles and material considerations.

Select appropriate materials based on application requirements, considering factors like UV resistance and mechanical properties.

Test prototypes in real-world conditions and iterate designs based on performance feedback.

Results & Achievements

Successfully repaired friend's broken hood release lever with reinforced design

Redesigned curtain mounting parts with integrated rivet nuts for superior strength

Created durable RC car control arms that outperform original parts

Developed rapid prototyping workflow with 40-minute print times

Applied engineering principles to achieve cost-effective, long-lasting solutions

Project Gallery

Images

Videos

Interested in Learning More?

I'd be happy to discuss this project in detail and share insights about my approach and methodology.